Infrared Thermography

Thermography is a well-established and safe technique of Non-Destructive Testing (NDT) for electromechanical equipment, electrical panels and installations.

It is a modern diagnostic method for preventing and detecting faults of mechanical and electrical equipment.

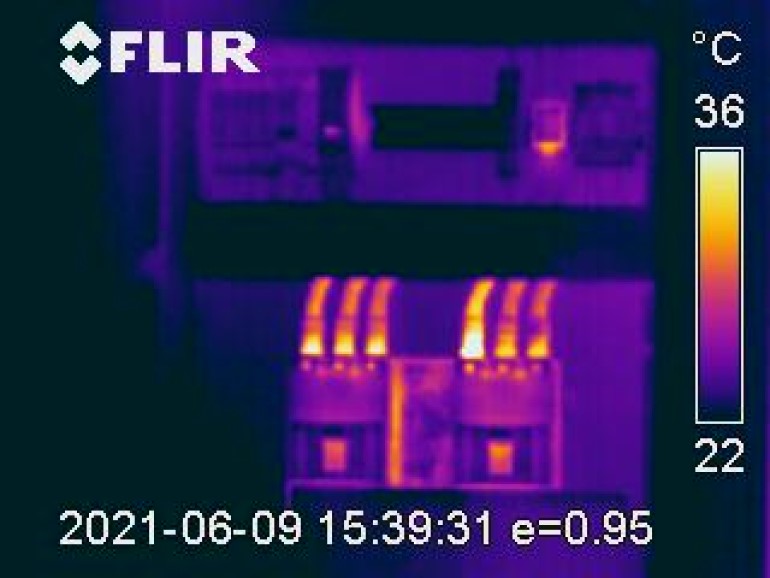

It is carried out by measuring the emitted thermal radiation with certified and calibrated equipment of advanced technology (thermal camera), which gives the possibility to thermally visualize the state of the facilities, in terms of the above-mentioned malfunctions.

Most of times, temperature raises as a usual consequence of electro-mechanical equipment’s abnormal operation. When equipment’s temperature raises, thermal radiation increases as well, but it cannot be visually detected.

Thus why, with thermography, any source of thermal radiation could be detected directly, without the isolation of inspected equipment, providing the ability of detection and valuation of the cause related with equipment’s temperature rise.

It is ensured then that equipment will be properly maintained in time, before any malfunction occurs at the installation.

Thermography of electrical equipment ensures its reliability and protection against accidents, whereas enhances control and prevention of unexpected damages and protects production from any profit loss.

Infrared thermography is a way to detect faults that may occur on:

- Electrical equipment: e.g. loose or over tightened connections, oxidized or corroded contacts, damaged cables’ insulation

- Mechanical equipment: motors, pumps, fans or compressors faults

- Building facilities: e.g. walls openings, insulations, HVAC systems

Industrial Safety Department of Ergonomia consists of specialized and long experienced engineers – thermographers undertaking:

- Infrared thermography in real time at client’s facilities by use of certified and high qualified FLIR’s thermography device with equipment’s infrared display.

- Taking of infrared photos for archiving or future comparison purposes.

- Analysis of infrared photos using FLIR’s software.

- Study report elaboration and delivery, which contains table of the detected faults as well as suggested repair, maintenance or replacement actions.